The Grand Tracker

What started a beat up Suzuki Grand Vitara has turned into a TTB Chevy Grand Tracker.

This is James with T&B Fab, and if you’ve been following us on Instagram, you’ve probably seen a few clips of the Grand Tracker. After a flood of questions, it’s time to do a full walkaround and dive deep into what makes this rig tick. What started as a Suzuki Grand Vitara has now become something entirely different—built in a home garage, using nothing but a grinder, welder, and a whole lot of stubbornness.

The Build List.

Custom Off-Road Body & Exterior Components:

- T&B Fabrication 1.5″ x .120 wall mild steel rock sliders for maximum underbody protection

- T&B Fabrication 1.5″ x .120 wall mild steel rear bumper with integrated tire carrier and ZOR swing spindle

- T&B Fabrication 1.5″ x .120 wall mild steel front bumper with integrated Warn 8000lb winch

- RodLouver custom hood louvers for improved engine cooling

- Auxbeam LED light bar for off-road visibility

Off-Road Tires & Custom Wheels:

- 33×12.50R15 Falken Wildpeak ATW4 All Terrain tires

- American Racing Ansen AR969 custom wheels

Turbocharged Engine Build & Performance Upgrades:

- 2.5L V6 engine with 160,000 miles, upgraded with MLS head gaskets

- Custom turbo setup: T3/T4 turbocharger running 10 PSI boost

- Aftermarket intercooler for improved performance

- Premier Power Welder alternator with onboard welding capability

- TC power steering pump conversion

- 4-core aluminum radiator for enhanced cooling

- AEM FIC 6 Fuel and Timing Piggyback ECU tuned by T&B Fabrication

Heavy-Duty Transmission & Drivetrain:

- Rebuilt 03-72LE automatic transmission with upgraded Mitsubishi 23-spline output shaft

- Mitsubishi NP transfer case adapter plate

- T&B Fabrication custom transmission crossmember and mount

Transfer Case & Crawl Ratio Setup:

- Jeep NP231J transfer case from 1990s Cherokee

- Slip yoke eliminator (SYE) kit installed

- 6-pinion planetary gears for strength

- Terra Flex 2:1 low range shift fork

- 2.71:1 low range crawl ratio

- 1350 U-joint rear output yoke

- 1310 U-joint front output yoke

- JB Custom Fabrication transfer case shifter

- Dakota Digital speedometer conversion box for Jeep to Suzuki compatibility

Custom Driveshafts:

- Arizona Driveshaft custom front and rear driveshafts

- Double-cardan (CV) joints at transfer case

TTB Front Suspension & Axle Build:

- 1990 Ford TTB (Twin Traction Beam) Dana 44 front axle conversion

- Full frame section from firewall forward with 6-bolt spindles

- Motive Gear 5.13:1 ring and pinion gears

- Spartan mechanical locker for improved traction

- T&B Fabrication plated and reinforced TTB beams with cut-and-turn modification (built with Nate Morgan)

- Desolate Motorsports uni-ball beam pivots

- T&B Fabrication 2″ x .250 wall DOM radius arms with 7/8″ FK heim joints

- T&B Fabrication 1.5″ x .120 wall 4130 chromoly engine protection cage

- Minhworx modified steering gearbox with heavy-duty ambulance tie rod ends

- King Racing 3.0″ Internal Bypass coilovers with 12″ stroke

- Fox Racing 2.0″ hydraulic bump stops with 3″ stroke

- 16 inches of front wheel travel with bump stops and limiting straps

Ford 8.8 Rear Axle & 3-Link Suspension:

- 2001 Ford F-150 8.8″ rear axle with redrilled axle shafts for 5×5.5 bolt pattern

- Motive Gear 5.13:1 ring and pinion gear set

- Spartan mechanical locker

- Iron Rock Off-Road axle truss for added strength

- Custom 3-link suspension with Panhard bar (track bar)

- 2″ x .250 wall DOM steel tubing for lower links

- 1.5″ x .250 wall DOM steel tubing for Panhard bar

- 7/8″ FK heim joints on lower links

- EMF spherical joints on upper link and Panhard bar

- Fox Racing 2.0″ coilover shocks with 14″ stroke

- Fox Racing 2.0″ hydraulic bump stops with 3″ stroke

- 15 inches of rear wheel travel

Functional Interior & Expedition Equipment:

- Complete spare parts kit, fluids, hand tools, and mobile welding equipment

- Fully operational air conditioning and heating system

- 2000-watt power inverter for tools and equipment

- Icom IC-8000 50-watt two-way radio for trail communication

- Polk Audio 6.5″ speakers throughout vehicle

- 10-pound CO2 tank for air tools and tire inflation

- Onboard angle grinder and drill

- Yeti 45-quart premium cooler

Front-End Overhaul: TTB Conversion

I started by cutting the entire front end off the Grand Vitara. From the firewall forward, it’s no longer Suzuki. Instead, I grafted in a stock full frame section from a mid 80’s Bronco from TT Motorsports (thanks Tommy!) to allow me to use the Dana 44 Twin Traction Beam (TTB) setup. This gives me 16″ of wheel travel, a strong front diff/axles compared to stock suzuki, and a track width that is not ridiculously wide — its way better than the factory McPherson struts could dream of for my situation.

The beams were completely torn apart, parts removed I didnt need, and rebuilt using uniballs from Desolate Motorsports, TTX ball joints, Spicer u-joints, and Timken wheel bearings. With the help from my good friend Nate Morgan, a complete beam plate kit was designed and cut with good ol’ cardboard-aided design (CAD), and everything was welded right here at the home shop.

Front Suspension and Steering Setup

Up front, we’re running King 3.0 internal bypass shocks with 12 inches of stroke, pulling 16″ of travel, bumped and strapped. Accutune did the valving and just about nailed it. Fox 2.0 bump stops with 3″ stroke help keep everything in check. Limit straps are installed, of course. Radius arms are custom built: 36″ long, 2″ diameter, .250 wall tubing with FK 7/8″ heims.

The steering tie rods are replacement versions of the ambulance model—beefier components, bigger joints, and connected to a 3″ drop pitman arm. A quick google search will bring up a few good thread on part numbers for these steering parts. Minworx in Apache Junction rebuilt the steering box, modded the box for easier turning on 33’s/rock crawling and even added ports for future hydro assist. For now, it’s working just fine without it.

Rear Axles, Suspension & Driveline

Both front and rear diffs are geared to 5.13s with Spartan lockers. Drive shafts are custom units from Arizona Driveshaft, Front using 1310 at the t-case, 1350 at the diff. Rear using a 1310 DC joint at the t-case and 1350 flange yoke at the diff. The front uses stock axle shafts with Mevotech TTX ball joints. Since we’re only running 33s, the stock axles should hold up just fine.

In the rear, there’s a Ford 8.8 axle from a 2001 F-150. I re-drilled the axles and drums to match the 5×5.5 bolt pattern up front. It’s got the same gearing and locker setup as the front. Suspension out back uses 14″ Fox 2.0 coilovers, valved in-house, and 2″ x .250 wall links in a three-link configuration with a panhard bar.

Engine & Turbo Setup

The original 2.5L V6 is still in there, but it’s been turbocharged with a T3/T4 setup. Exhaust from the passenger side comes out of the stock manifold, out the flange jsut past the cat and then routed back up into the driverside manifold. This all loops under the transmission very similar to stock exhaust routing. A T3 flange is welded to the driverside exhaust manifold, then exhaust gasses come out through the t3 flange, to the turbo and back down the turbo down pipe. It’s not conventional, but it works extremely well.

Engine management is handled by a piggyback AEM FIC6. Running 10 PSI of boost on 91 octane, with room to go higher. Blow-off valve, wastegate, and factory fuel pressure regulator are all in place as well.

Cooling, Power Steering, and Welding on the Trail

Cooling is handled by a oversized drop-in eBay radiator that dropped temps from 230° to around 200° during the summer—a big deal in the Arizona heat. The stock power steering pump couldn’t keep up, so it was replaced with a Jeep TC-style unit mounted on a custom bracket i made.

One of the most practical additions is a Premier Power Welder. I run trails deep in the desert, sometimes solo, and having on-board welder means its going to be very hard to be stranded. It uses a 160-amp modified factory alternator that bolts right in and powers the welder directly.

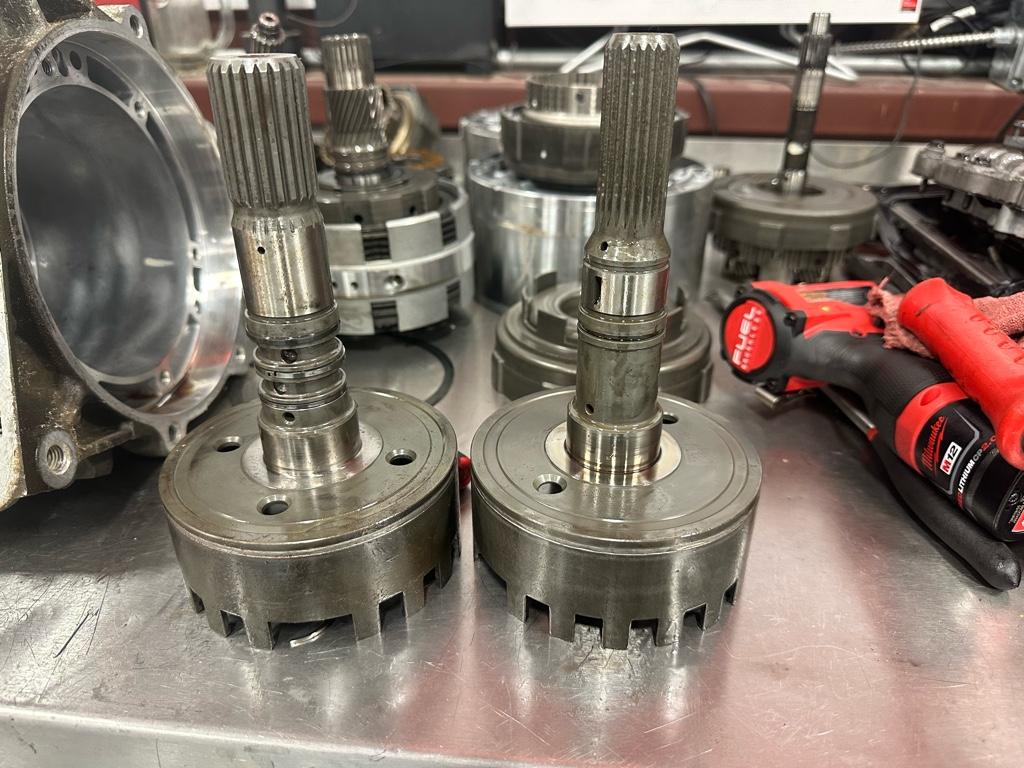

Transmission & Transfer Case Magic

Still running the stock 4-speed automatic, but here’s the trick: the transfer case behind it is a Jeep 231. To make that work, I used an output shaft from a Mitsubishi Montero (late ’80s/early ’90s) that happens to match the Jeep 23 spline output. That transmission is the full hydraulic version of the Suzuki 03-72LE I have so putting that output shaft in was almost drop in. Slipped that into the Suzuki transmission, added a Jeep adapter, and everything fit together perfectly. A trans output speed sensor needs to be added, a couple holes plugged on the output shaft and t-case adapter will need to be sealed to both the trans and t-case with a drain back hole put in for trans fluid

The transfer case has a slip yoke eliminator, 1310 U-joints, and a JD Fab shifter setup. It also includes a Teraflex 2-low/4-low fork so I can have 2 low while out crawling.

Body, Bumpers, and Rear Tire Carrier

The bumpers, rock sliders, and rear tire carrier were all built in-house. The rear bumper tucks tight and raises the fuel tank 2.5″ for better clearance. The tire carrier is integrated into the door with a cradle and pivot system to keep it rock solid even at speed but opens with the rear door without any additional levers or locks

Frame plating was done front and rear with 1/8″ and 3/16″ steel to keep the chassis from flexing under abuse. The rig’s been wheeled hard for years and it’s held up great.

Interior: Purpose-Built and Practical

Inside, it’s all about function. It’s not flashy, but it’s ready. The rear holds a 45qt Yeti cooler, ammo cans with tools, welding gear, spare fluids, a 10-lb CO2 tank, and whatever else the trail might demand.

Interior mods include a boost gauge, AFR, fuel pressure/oil pressure gauge, and a RAM mount with Gaia GPS. I run an ICOM V8000 VHF/UHF radio for long-distance comms out on trail.

Final Thoughts

This rig has been years in the making. From Frankensteining drivetrain parts across brands to solving real-world off-road problems in creative ways, the Grand Tracker is proof that you don’t need a big shop or massive budget to build something badass. It just takes time, the want for it and not being afraid to fail. Its been a 10 year process of constant evolution with lots of failures in-between but its come out working better than I ever thought possible.

Want to see more builds like this? Follow us on:

- Instagram: instagram.com/jimmys.caulk

- YouTube: youtube.com/@tandbfab

If you’ve got more questions, drop them in the comments or shoot us a message. We’re always happy to dive deeper and share what we’ve learned.

Stay up to date, we’re going to be posting more updates on The Grand Tracker on our web site!

No post found!